Monitoring gauge and calibration equipment with TDM offers high added value

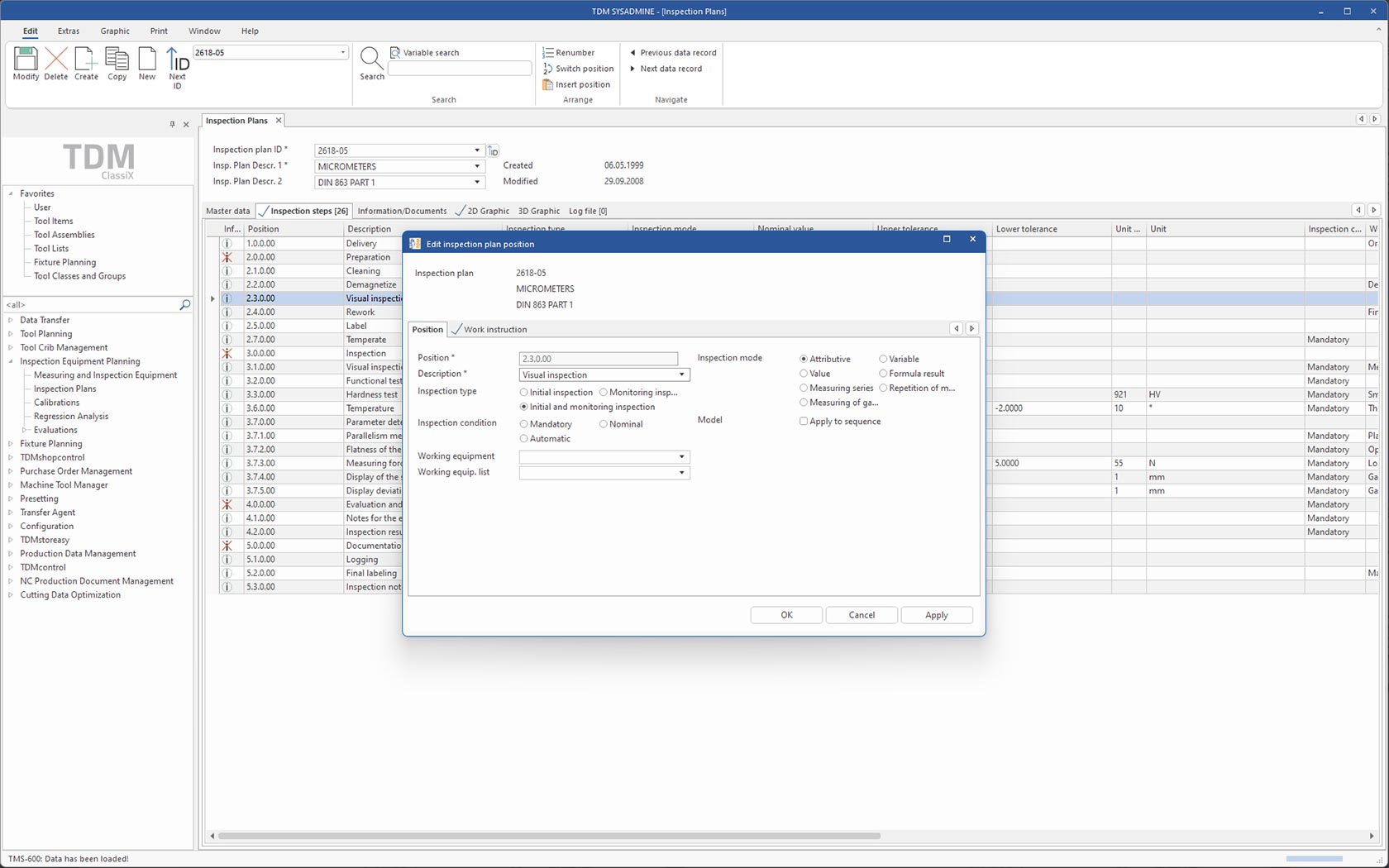

The module systematizes gauge and calibration equipment management, thereby ensuring secure and completely reliable quality assurance at all times. Advance calculation of the inspection timing represents the basis for the precision of the gauge and calibration equipment. Integrated plans for performing testing and calibration are just as important. You can then rely on transparent and cost-effective monitoring of your gauges, measuring and calibration equipment.

Simple gauge and calibration control monitoring thanks to a variety of functions

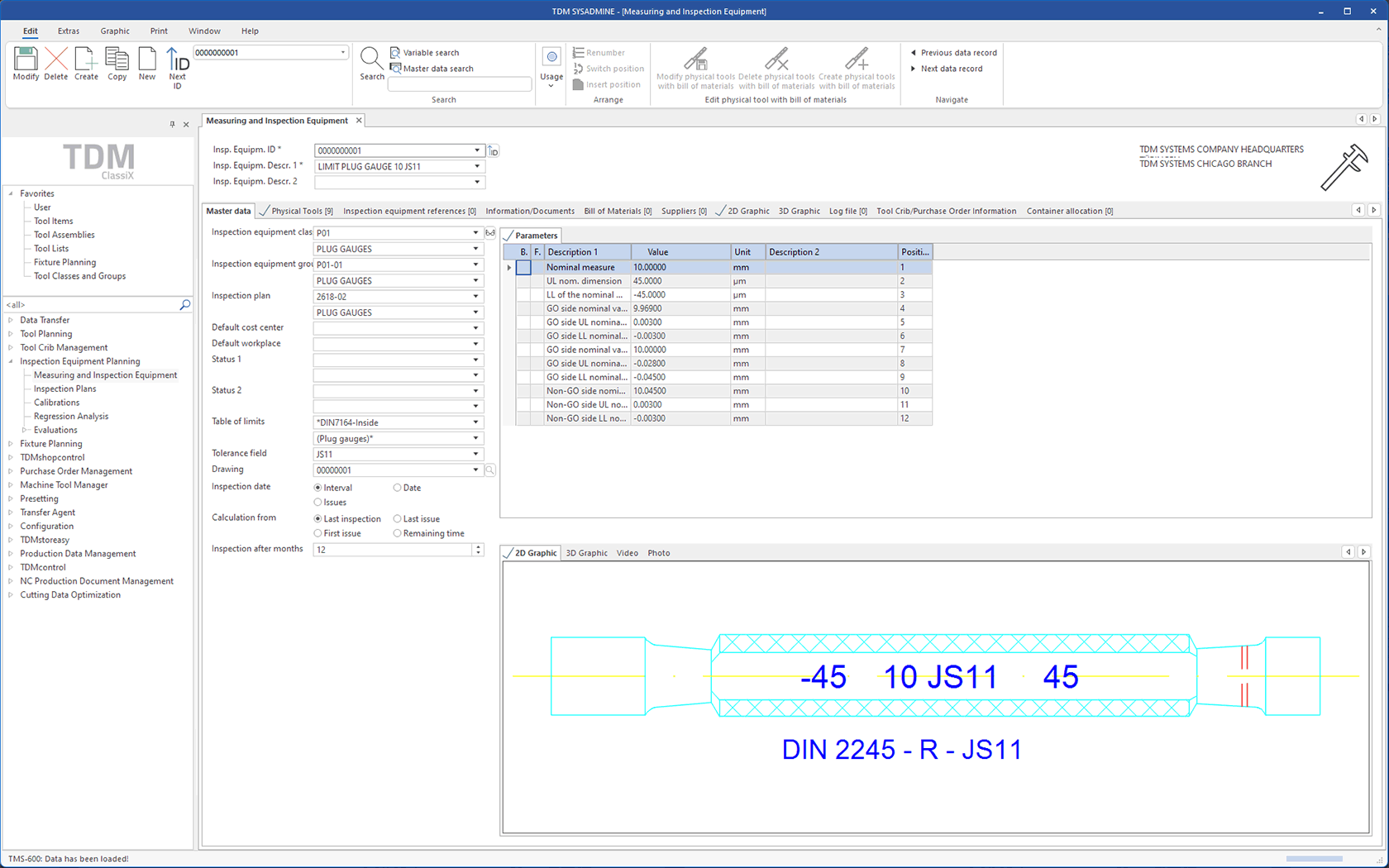

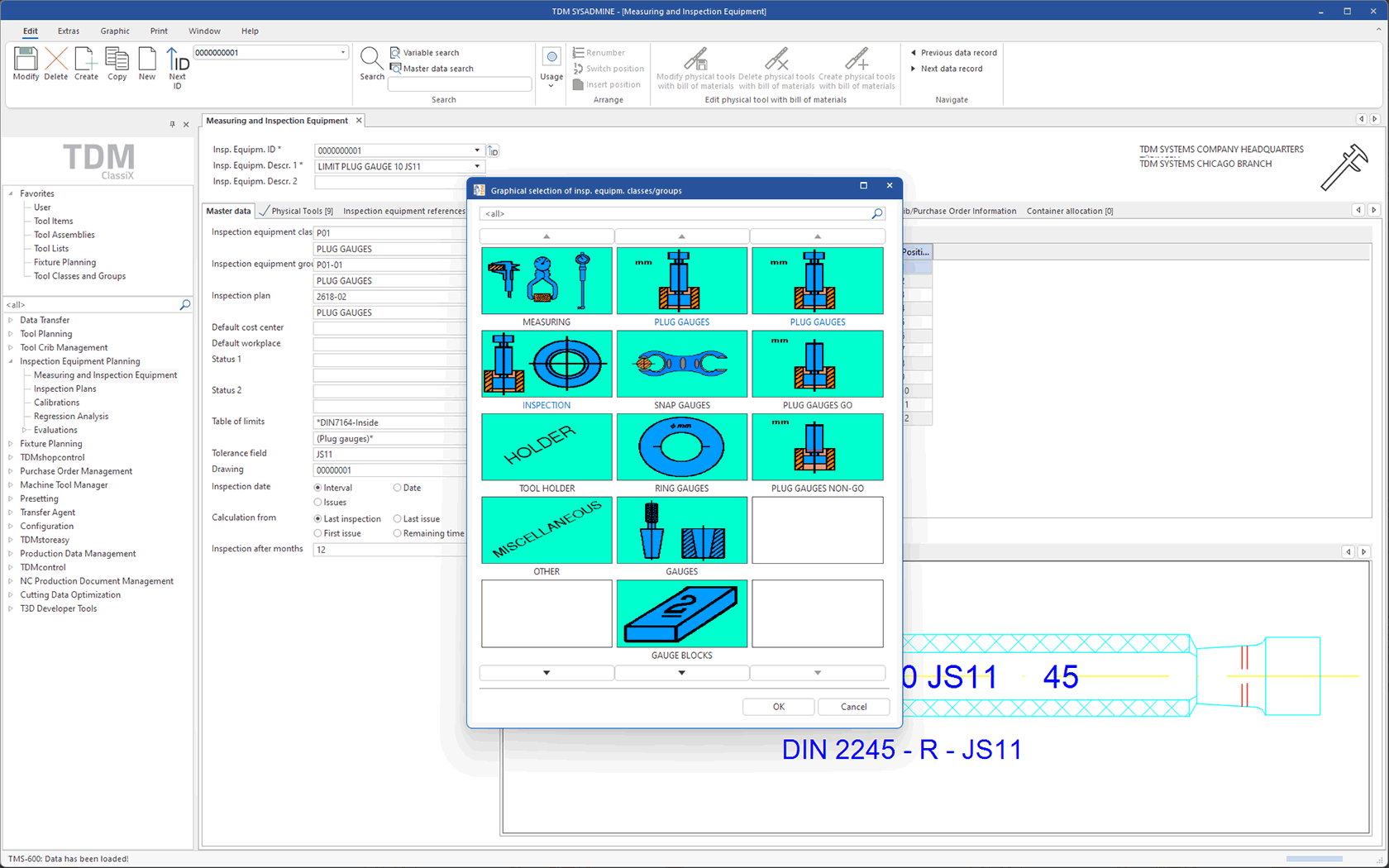

Comprehensive basic data, such as master data, inventory data, parameters, pick lists, graphics, or gauge and calibration equipment references, are a component of this reliable management tool. The software comes with a range of predefined basic data. This includes a class and group structure for gauge and calibration equipment or dynamic inspection intervals and tables of dimensions.

Optimized processes

The software is intuitive to use and compatible with the Tool Crib Module. The Gauge and Calibration Control module ensures that gauge and calibration equipment is ready for use. Thanks to compatibility with the Tool Crib Module, you can see where the gauge and calibration equipment is currently located, who is using it, and who has requested it. This also helps you achieve a high degree of process reliability for gauge and calibration equipment.