Organize fixtures through comprehensive functionality

You save all information that you require in order to structure, maintain, yet also search for a suitable fixture in the fixture master data. The module is fully connected to the Tool Crib Module, providing you with information on the location of your fixtures in the crib at any time.

Fixtures are entered in tool lists together with the other operating equipment, so that you can keep the right tools and fixtures available for each production order and book them for a machine.

Data for efficient management

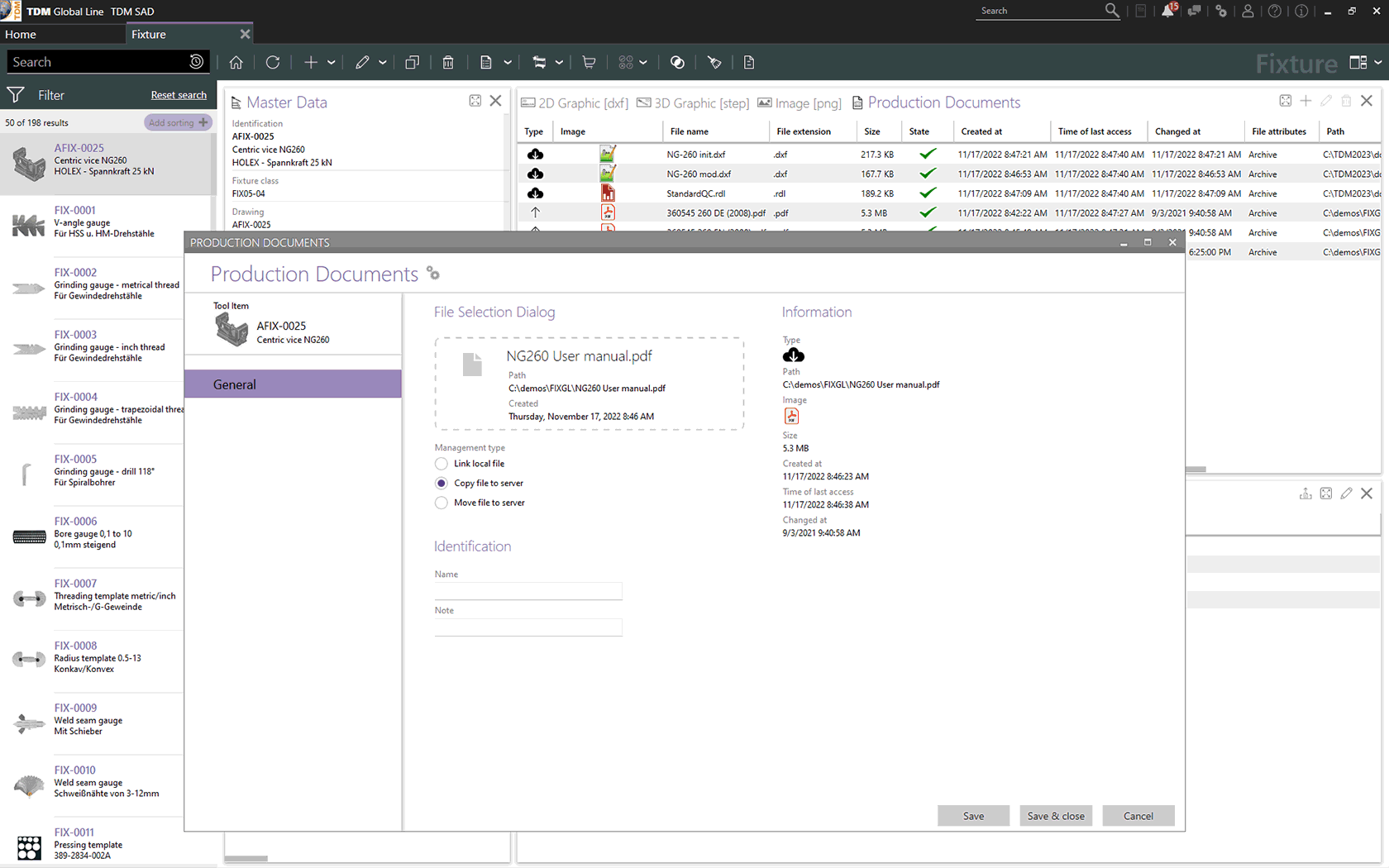

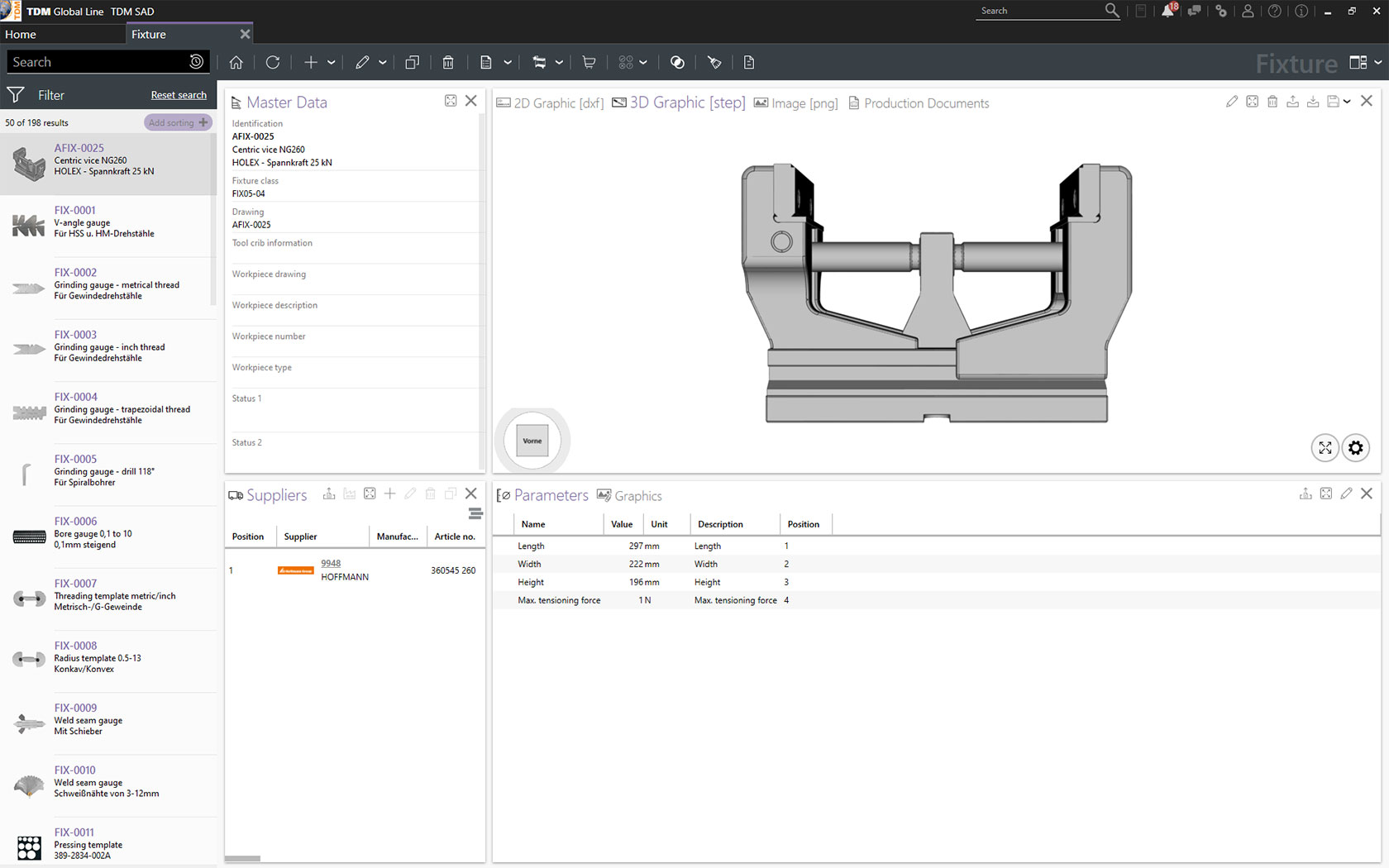

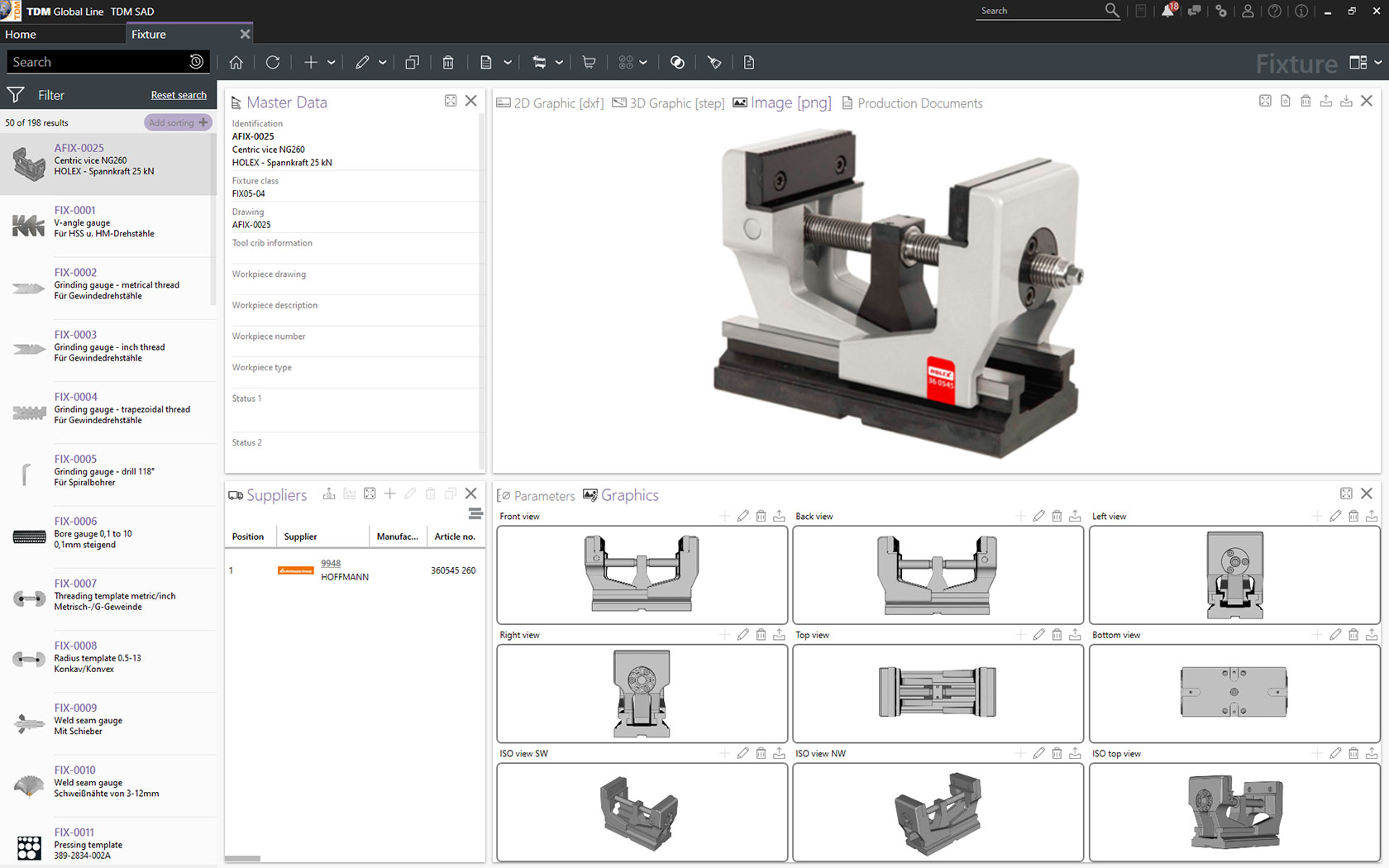

The fixture master data contains all parameters, documents, and information that you require in order to find a suitable fixture and then make it available on the shopfloor.

A class structure for fixtures is also provided. This makes it easier for you to select the parameters. You can of course also adapt this class structure to your own requirements or use your own classes.

Similarly to tool management in TDM, each fixture master data record contains a pick list, which includes all individual items of that fixture.

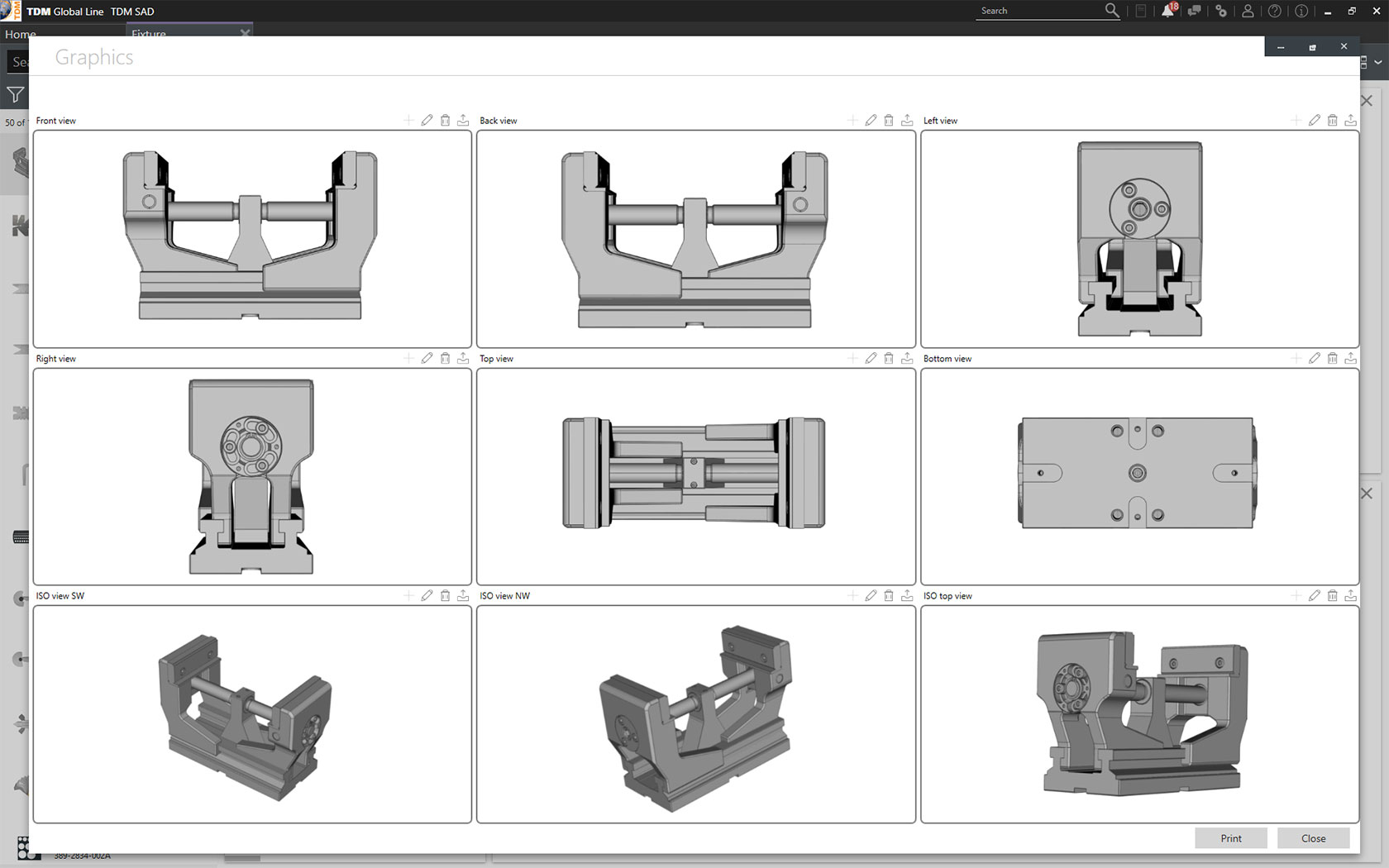

Additional 2D graphics and 3D models, blueprints, and perspective views of the fixture document its assembly and setup.

Information on suppliers of the clamping devices supplements the data and also ensures that the fixtures section is ready for the ordering system.

If desired, you can also enter modification notes, so that all changes to a clamping element are logged and comprehensible.

Option: Cyclical checking of fixtures

Some fixtures or clamping elements need to be checked and maintained at regular intervals. These include fixtures which contain electrical elements, pressure accumulators, or similar elements, as well as those which must be capable of delivering a defined clamping force. The TDM Fixture Management Module can optionally also manage and monitor the necessary maintenance intervals for such clamping elements. The clamping elements due for a check are then displayed to the operating personnel, so that the maintenance can be performed at the appropriate time. All documentation necessary for performing the maintenance can of course also be managed with the TDM Fixture Management Module, for example in connection with TDM Production Document Management.

Currently not available for the TDM Fixture Module Global Line.