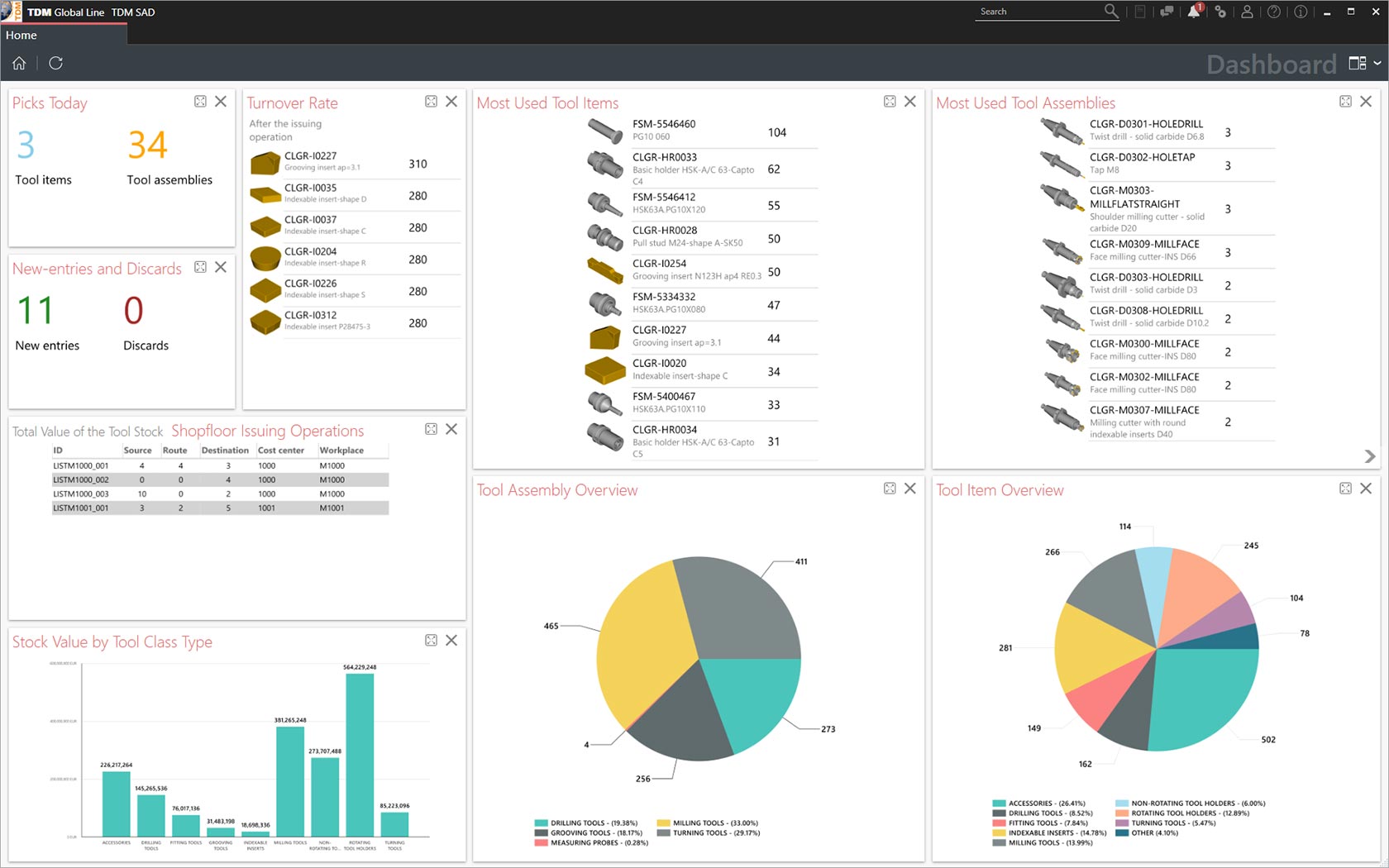

Tool data for all smart production requirements

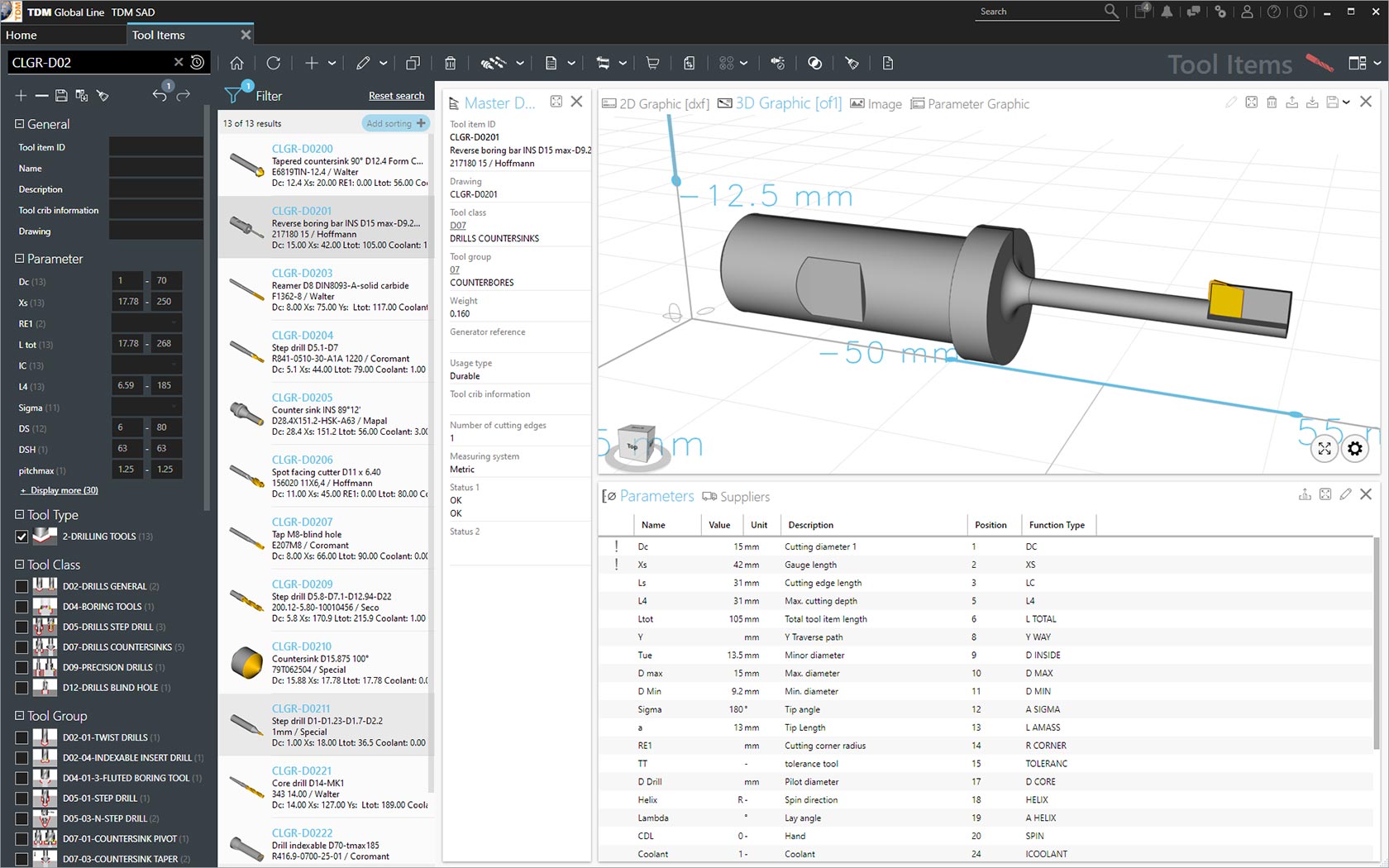

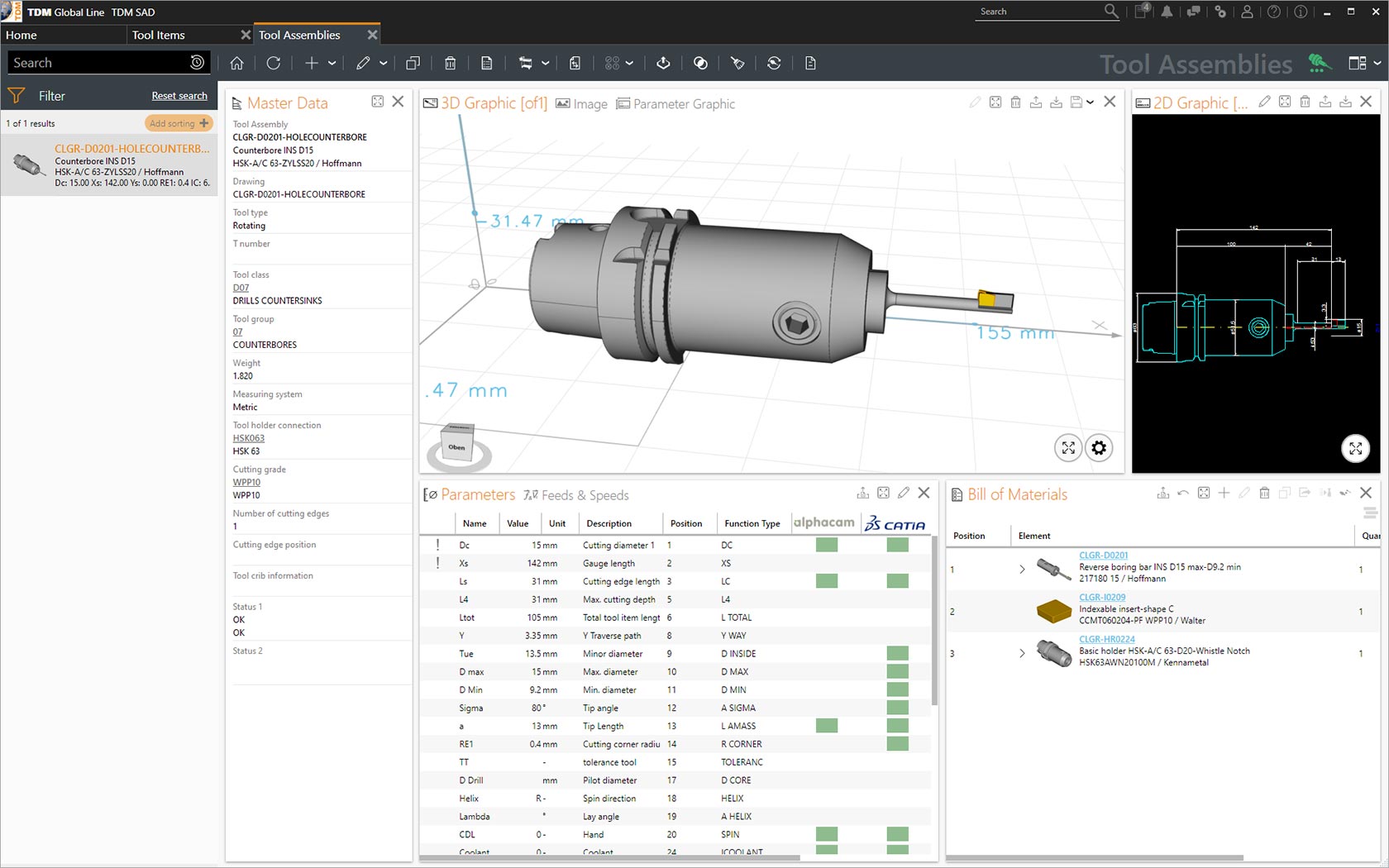

A central database sits at the heart of the TDM Base Module Global Line. It keeps the real tool data available as a digital twin for all departments involved in the production process. Numerous interfaces secure data exchange at both planning and production level. Tool data requirements vary from department to department. The TDM Base Module depicts these in its data structure and manages tool items, tool assemblies, and tool lists at various levels. Each data level offers users comprehensive options for defining and storing information, data, photos, etc.

Optimizing production processes: Assembling tools with just a few mouse clicks

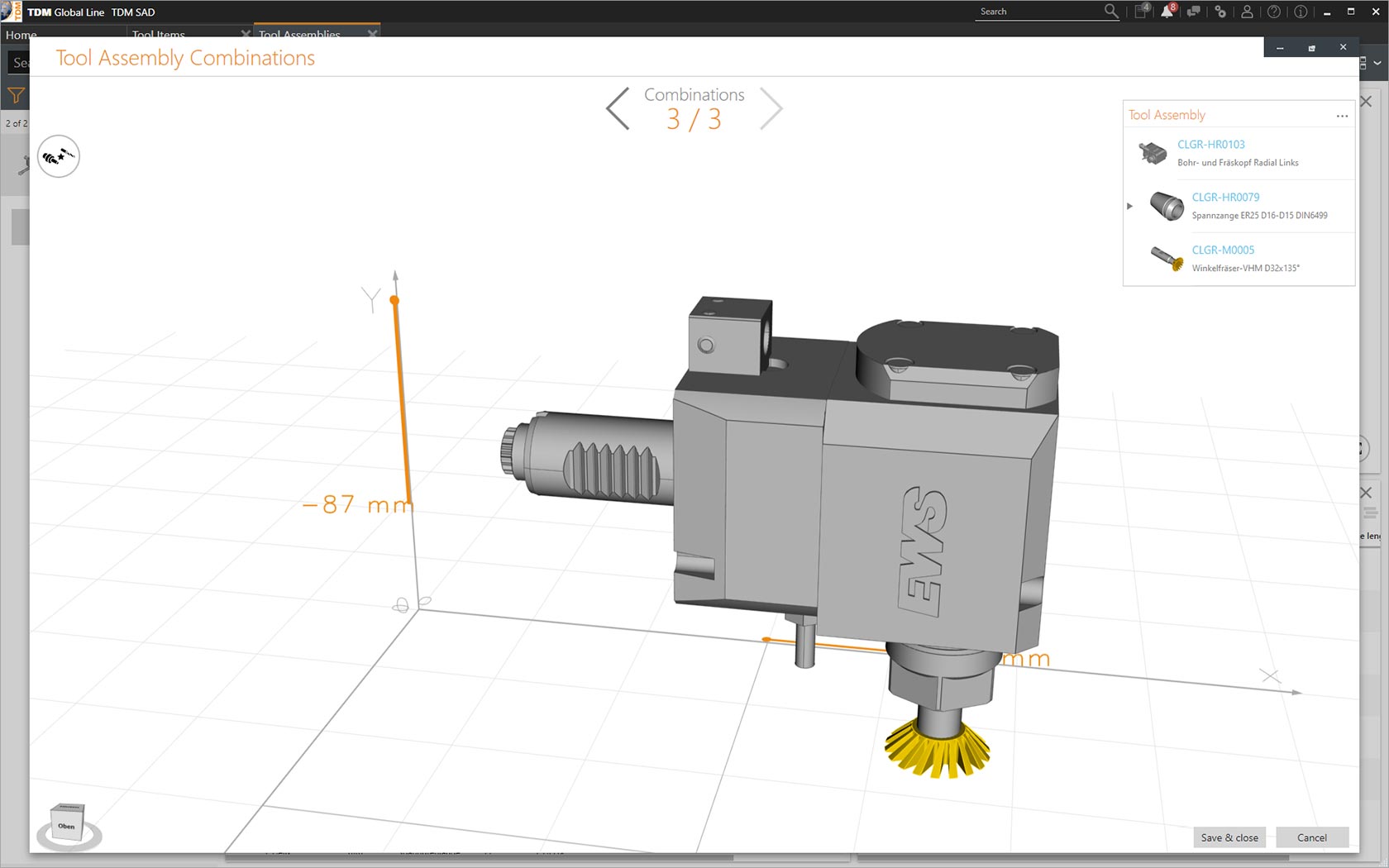

Feedback from users is also incorporated in the continuous further development of the cutting tool management software. The focus here is always on logical functions and their ease of implementation. This helps us achieve the objective of enabling users to assemble tools with just a few mouse clicks. This also applies equally to defined tools and tool assemblies.

Smart production - The TDM Base Module Global Line in use

Companies looking to compete with the big players in the age of Industry 4.0 and digital twins have no other choice than to optimize and digitize their production. The benefits of tool management with the TDM Base Module Global Line are clear: