FMS integration increases productivity

FMS are characterized by the fact that they can process a varying workpiece spectrum on several machines in parallel. Usually, these systems have appropriate storage facilities for workpieces and tools, so that unmanned operation is also possible for a certain period of time.

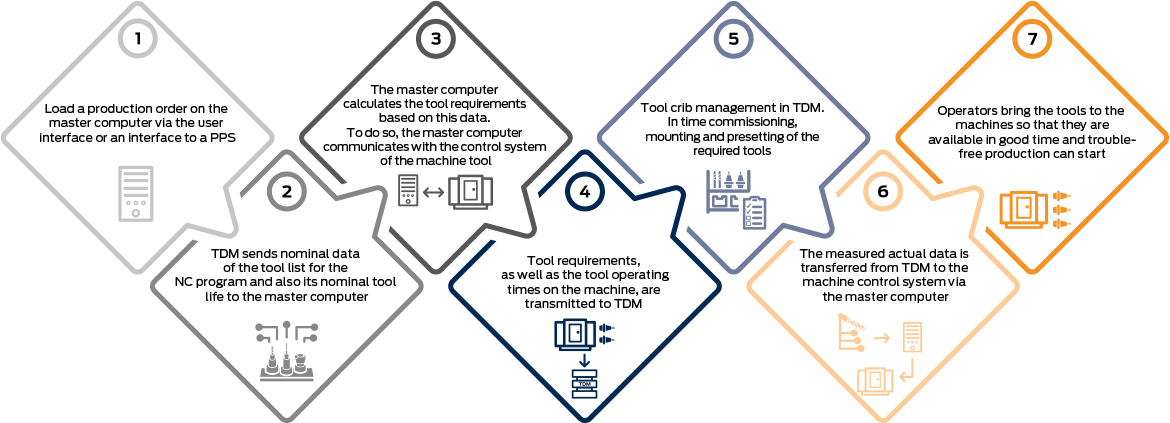

Procuring such a system usually means a major investment for a company. The productivity of flexible manufacturing systems is therefore of particular importance. The resources required for production, such as NC programs, fixtures and tools, must be provided in good time and in sufficient numbers. Interfaces between TDM and the systems' master computer make the necessary tool requirements transparent. Both in terms of the number of tools and when they are needed. This is particularly true if all tool data is stored in a single, central TDM database that can access the flexible manufacturing systems' master computers.

TDM provides standardized interfaces to the most common manufacturers of control systems for flexible manufacturing systems such as Fastems, Liebherr, Promot, Soflex, etc. As far as providing the tools is concerned, customers can rely on solutions that the respective manufacturers maintain and develop further. Such integration generally consists of the following parts:

Tool coding makes sense.

Flexible manufacturing systems are often the most expensive production facilities in a company. Therefore, the users try to avoid everything that could lead to disruptions in the production process. Additional investment in coding the tools is therefore justified for such systems. TDM supports all common variants, regardless of whether they are fixed coded holders or read/write systems.

Fastems

To provide the required tools, a master computer communicates with TDM directly via an XML interface. Fastems plans the tool requirements for the dispatched orders and sends the requirements list to the TDM software. This makes the tool data available for all systems:

- Employees assemble the tools at a TDM workstation.

- When the assembly process is acknowledged, the tool appears in the production list, which in turn is visible on the presetting device.

- The operator can measure the tool.

- Tools unloaded from the Fastems cell can also be retrieved.

- Based on this information, the tool can be disassembled or stored as a tool assembly.

- The tool circulation in production is therefore closed.

SOFLEX

Based on the tool assemblies created in TDM, the NC program can be used to create the corresponding tool lists.

- The production control system plans an order which is released by SOFLEX and requests the tool list from TDM.

- The interface transfers this to SOFLEX.

- The system then identifies the required tools and transfers this information back to TDM. This allows the tools to be assembled, preset and measured.

- The actual tool data is automatically sent to the SOFLEX control system.

- As soon as the tools are loaded into the machine magazine, the respective order starts.