Assemble your individual special cutting tool in just a few steps

The process for generating individual 3D models is virtually automatic with the TDM 3D software. Users can then generate a tailor-made special tool with just a few mouse clicks.

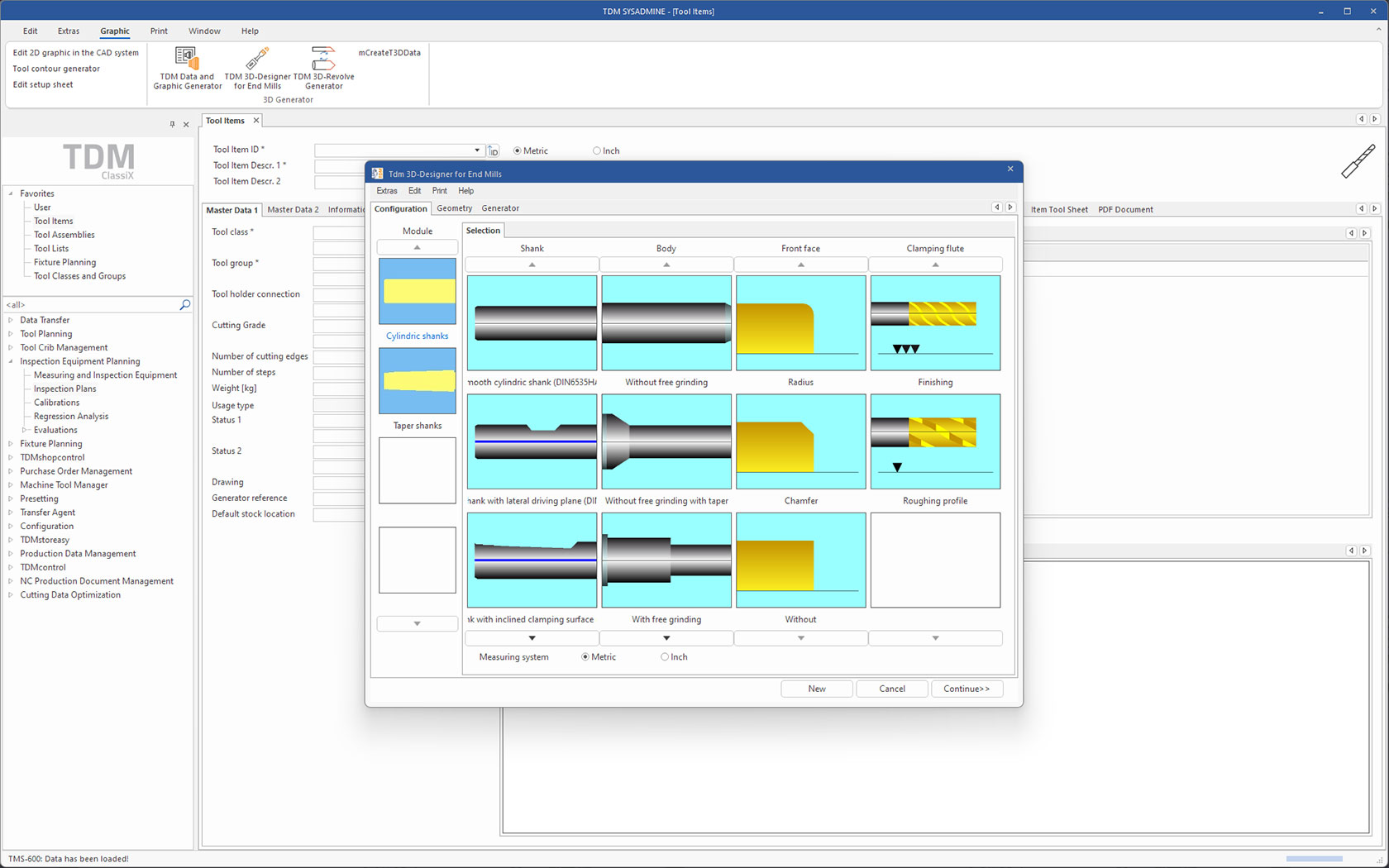

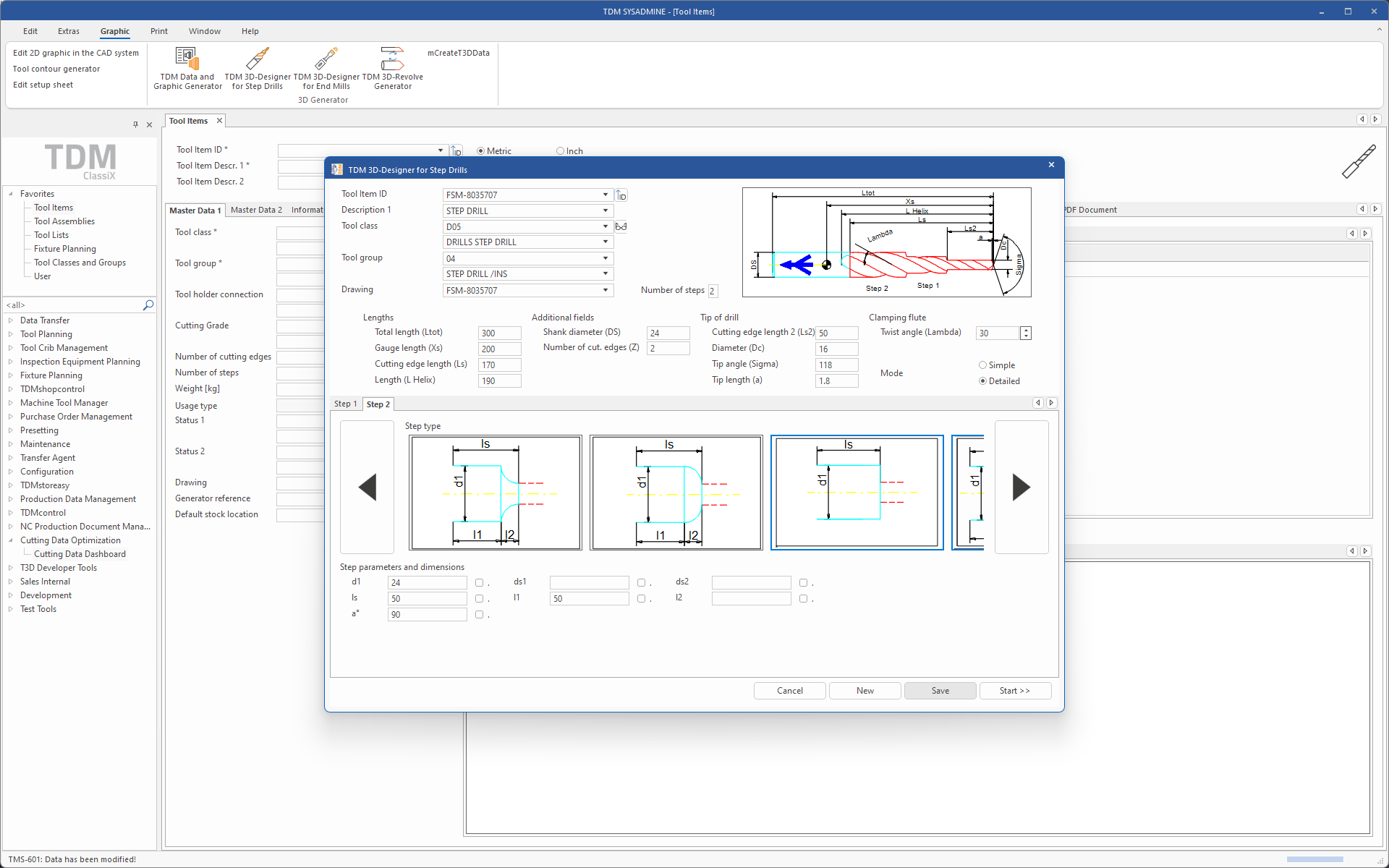

- Assembling individual tools: With just a few mouse clicks, you can select the individual workpieces, such as shank type, body, face, chip grooves on end mills, or the number of steps and transitions per step on step drills.

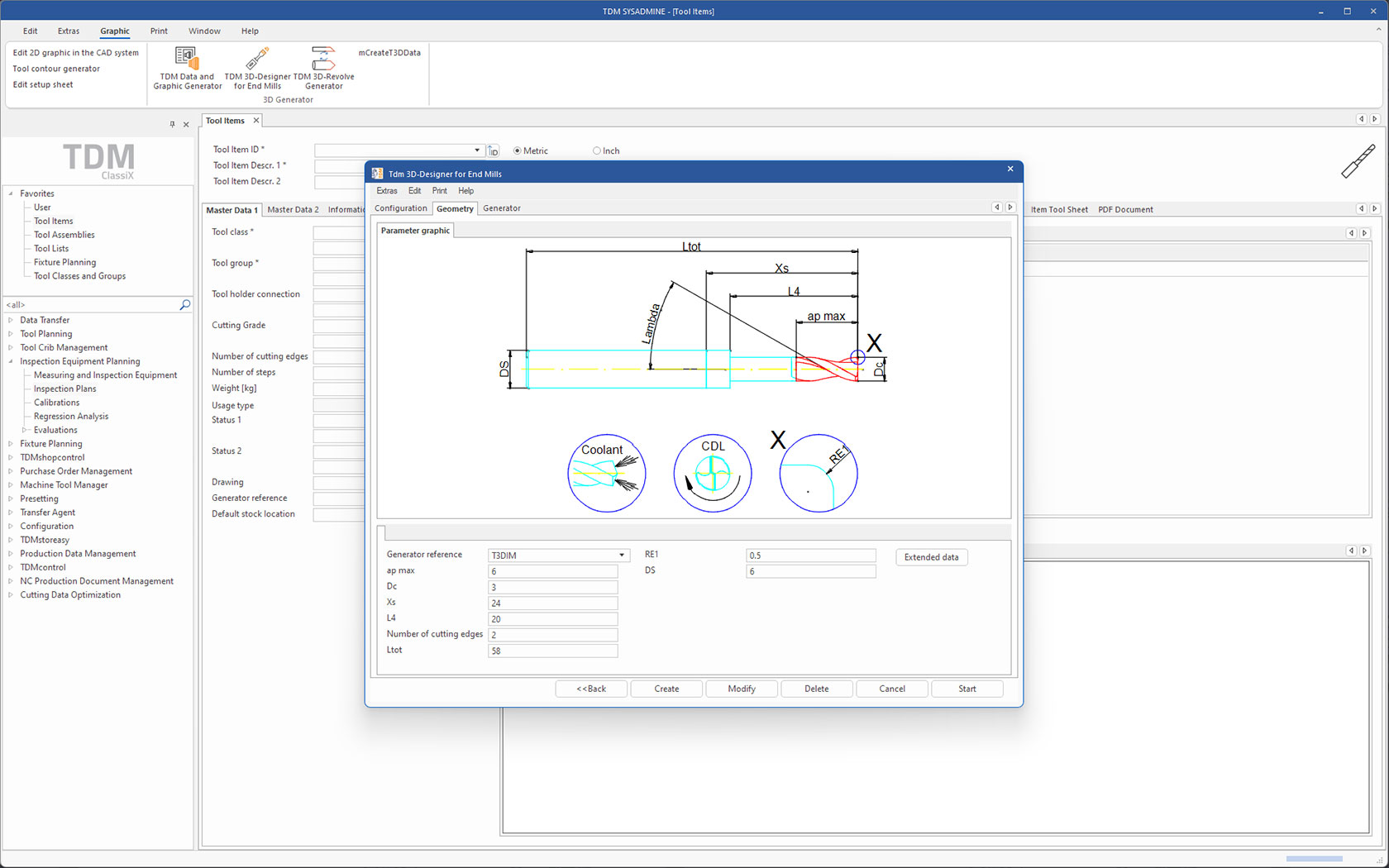

- Entering geometry: In the next step, you enter the geometric parameters for your tool manually, such as length and diameter.

- Individualizing tool parameters: You can now change existing tool parameters or define new ones. This produces an individual tool, tailored specifically to the required use.

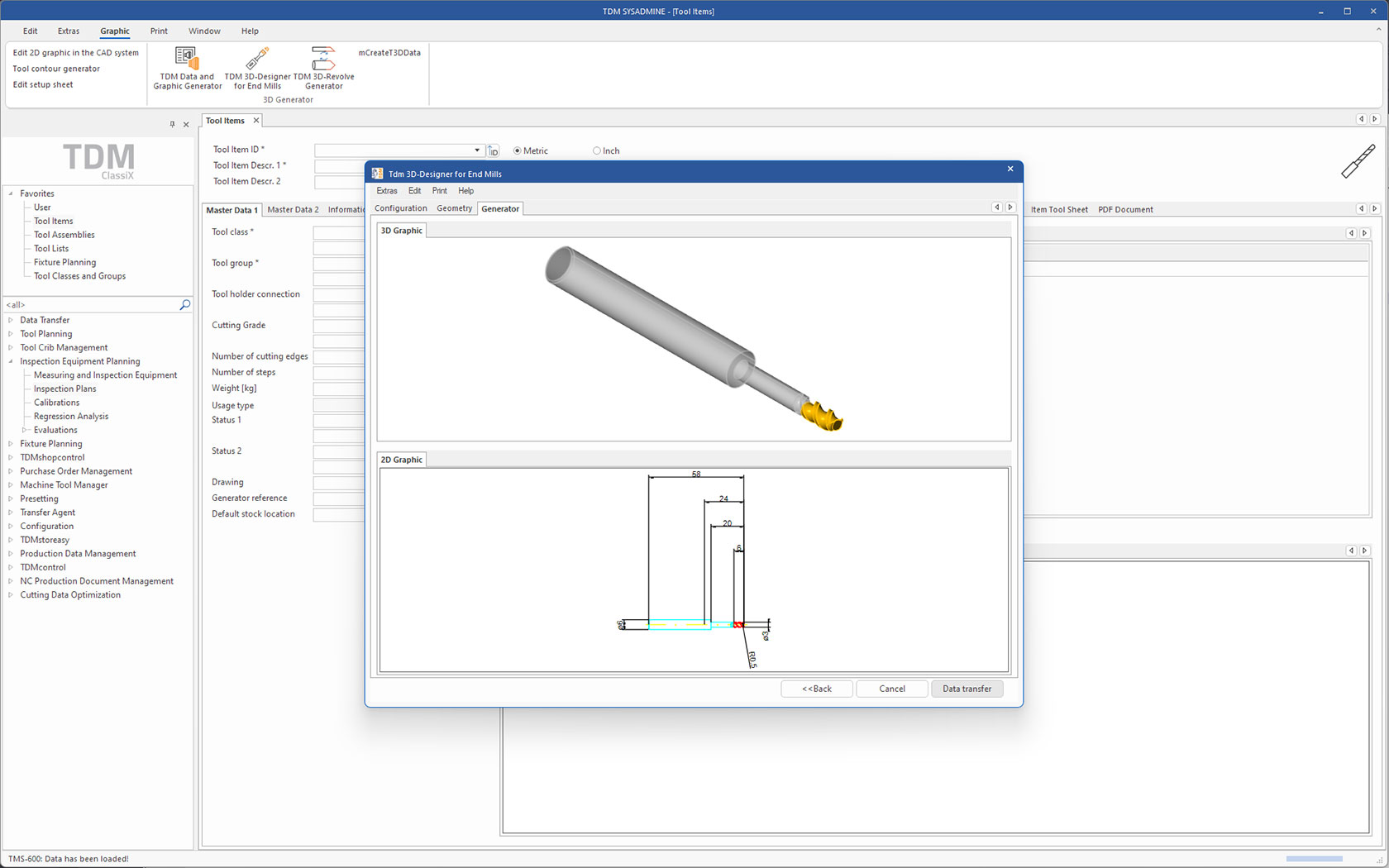

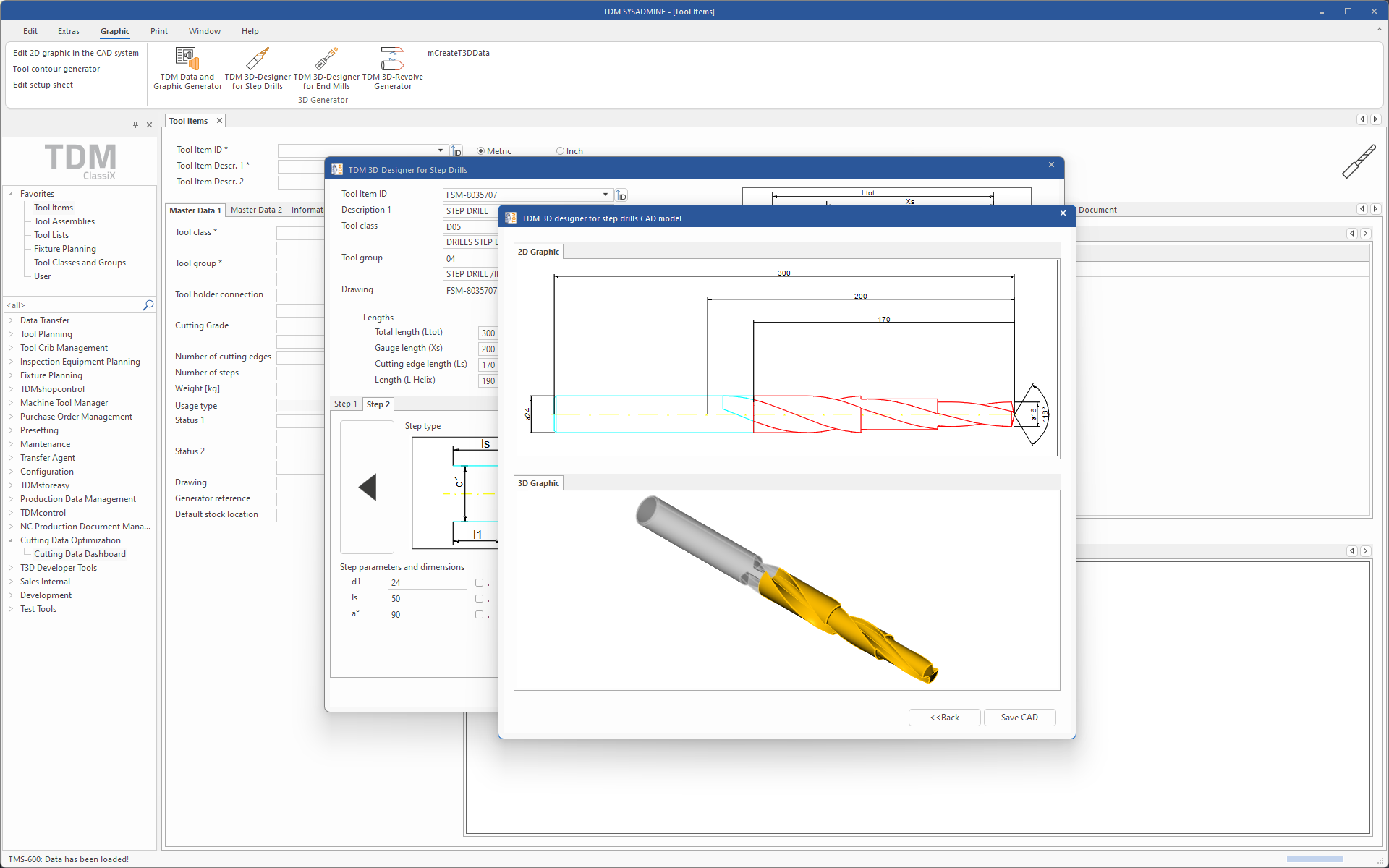

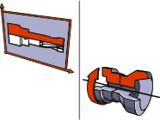

- Generating a tool: The TDM 3D-Designers automatically generate 2D graphics and a 3D model of the tool in multiple formats with a simple mouse click. The software also draws up a tool data record directly.

- Saving the tool: In the final step, the 3D-Designer saves the tool in the TDM database. The tool is then available for the TDM software applications.

The results are compelling: Users can use the tools generated in the form of 2D graphics and 3D models easily and in detail for NC programming and simulation.

Easily generating 3d special tools thanks to the high TDM functionality

The functionality of our TDM 3D-Designers for End Mills and Step Drills has been perfected through many years of experience. The properties that have been implemented for the respective modules on this basis facilitate fast and efficient work methods: