A common backbone for production units worldwide

In 2018, as part of a group-wide digital transformation, SECO Tools launched a pilot project at its Bourges site. This aimed to optimize production processes, through the use of TDM Systems' software - specializing in the management of cutting tools, gauges, calibration equipment and fixtures. Today, the employees of the production units at the Bourges plant have access to a common application and methods that provide them with more services. They have moved from laborious, manual, paper-based Excel files to a digital format with connected tablets that allow them to access reliable, centralized data whenever and wherever they need it.

Process optimization and productivity gains

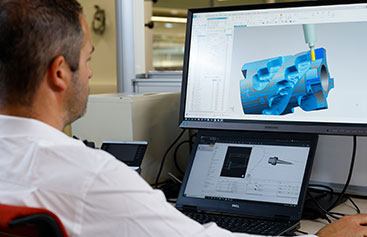

With TDM Systems, Seco Tools has an application that is designed to be a single source of information, giving everyone in the production facility access to the right tool data, at the right time and in the right place. Programmers gain speed of execution, reduce the risk of errors, and maximize machine utilization time. Thanks to the 3D visualization, it is even possible to locate each tool within the workshop, to know if it is being used and by which operator. As a result, expenditure on consumables has been reduced. With the same solution and methods being deployed at other sites, Seco Tools was able to gain flexibility.

Eventual global deployment

Once the process was matured in Bourges, the project began to be deployed in Pune (India) from servers hosted at Seco Tools' parent company in Fagersta (Sweden). As the database was already created and centralized on the same servers, both sites were able to use it immediately. In addition to optimizing IT costs, this centralization was very useful during the lockdown period as the project could continue to be deployed and controlled remotely.